ATP’s product offering of weld spatter-resistant fittings and tubing provides users a durable method of fluid and gas transfer in welding environments. Weld spatter tubing is designed to shed spatter or sparks created during welding processes.

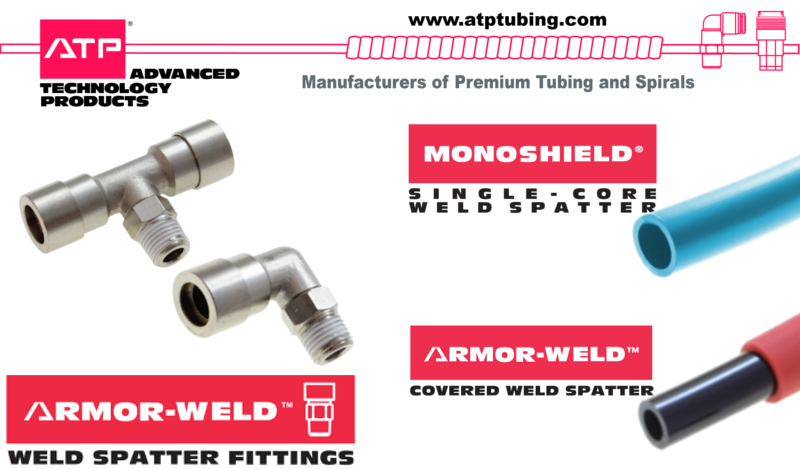

Monoshield™ is a single-core extrusion constructed of 98A polyurethane. Monoshield™ offers easy installation since there is no jacket required to be stripped. It should be noted that Monoshield™ should be installed in locations where indirect or occasional exposure to welding sparks occur.

Armor-Weld™ is a jacketed weld spatter tubing that contains an inner 98A polyurethane core, with a Olefin jacket. Although Armor-Weld™ does require an additional process of removing the jacket before installation, it is rated for direct exposure to welding sparks.

ATP recently released Armor-Weld™ Weld Spatter Push-to-Connect Fittings. These fittings are constructed of nickel-plated brass and feature a release ring with a protective cover. The protective cover prevents ingress of spatter and debris, preserving fitting operation. When Armor-Weld™ Tubing and Fittings are used in unison, there is no exposure of the polyurethane core after installation.

For more information, please visit the following links:

https://www.atp4pneumatics.com/product-category/fittings/armor-weld-fittings/